AMINSA Solutions for Industry

Focused on Cost, Quality and Delivery

E-COAT

Tube Bending

Metal Coatings

WE ARE AN

All-in-One solution for the Automotive Industry.

Learn more about us

OUR SERVICES

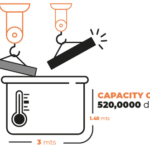

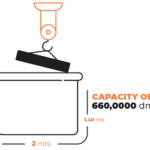

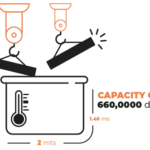

E - COAT

Electrophoretic Coating

“E-COAT”, Electrophoretic Coating, is a coating process widely used in industry to apply a uniform layer of paint or coating to a wide variety of metal products and components. The process is particularly popular in the automotive industry for parts that require corrosion protection.

Tube Bending

Innovative metal forming processes and headrest supports

We have the highest technology tube bending machines to achieve the quality our customers demand.

- Speed

Metal Coatings

In addition to offering the Electrophoretic Coating (E-COAT) service, we are specialists in metal coatings such as: Chromed, plating, zinc plating and Tropicalized.

chrome plated

Chrome plating is generally required for products in the automotive industry, white goods (main appliances related to cooking and household cleaning), agro-industrial, household appliances, among others.

Electrolytic Galvanized

This is a coating based on acid zinc with an electrolytic process. Acid zinc has a brighter finish than alkaline zinc, although the uniformity of thickness tends to vary slightly at different points. Its appearance is blue with iridescent tones due to trivalent chromate. It is usually used for greater durability and corrosion resistance.

Galvanizing is generally required for products in the automotive, white goods, agro-industrial, domestic appliances, food, machining and other industries.

Tropicalized

This is a zinc based coating produced in an acid tank using an electrolytic process. Acid zinc has a brighter finish than alkaline zinc, although the uniformity of thickness tends to vary slightly at different points. Its appearance is yellow with iridescent tones, it usually has more durability and corrosion resistance purposes.

AMINSA IS A COMPANY WITH A SOCIAL RESPONSIBILITY

At AMINSA, we are committed to the environment, which is why we have a water treatment plant that guarantees the cleanliness of the water from our processes without causing significant damage to our ecosystem.

LEARN MORE

Respect for the environment is a constant challenge, so in order to make adjustments and improvements, we periodically carry out discharge analyses with specialized and accredited laboratories to ensure that our plant achieves the desired result.

OUR CLIENTS

Interested in what we do?Let's talk!

Please contact us for additional information about our services.